Mobile cleaning > Why we? > Comparison LaserEcoClean

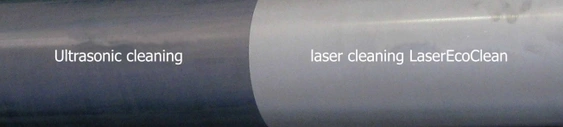

COMPARISON OF TWO TYPES OF DEEP CLEANING: ULTRASONIC CLEANING AND LASERECOCLEAN TECHNOLOGY

Bellow you can see the cleaning results of the anilox rolls with line screen 360 lpi and a volume of 4.2 vol.

The roll was cleaned regularly during the entire lifetime.

Comparison was made in the following way: Firstly, the roll was cleaned with ultrasonic cleaner. Than the half of the roll was cleaned with laser. Optical density was measured with a densitometer and by weighting.

On the printing unit was pulled the solid color and 6-7 measurements in the whole printed field were made under same printing conditions.

It was used ink cyan with 23 seconds ink viscosity. Printing speed 220m/min. Printing substrate: metalalic BOPP 15 micron.

Evaluation method | Ultrasonic cleaning | Laser cleaning after ultrasonic cleaning | Difference |

Ink transmission increase | 0,2 g/m2 | 0,4 g/m2 | + 0,2 g/m2 |

Optical density | 2,58 | 2,68 | + 0,10 |

Also the cleaning on the roll from another printing unit was made. The ink Pantone 072 with 23 seconds viscozity was used. Printing speed 220m/min. Printing substrate: metallic BOPP 15 micron. On the printing unit was pulled the solid plate and 6-7 measurements in the whole printed field were made.

Evaluation method | Ultrasonic cleaning | Laser cleaning after ultrasonic cleaning | Difference |

Measurements of the cells volume with Troika AniCam | 6,3 cm3/m2 | 7,0 cm3/m2 | + 0,7 cm3/m2 |

Optical density increase | 0,17 | 0,33 | + 0,16 |