Mobile cleaning > Why we? > Comparison LaserEcoClean

COMPARISON OF TWO DIFFERENT LASERCLEANING METHODS: LASER CLEANING WITH SCANING SYSTEM AND LASERECOCLEAN TECHNOLOGY

Some companies are using previous generation laser beam unit. As a result, they have another oscillating beam system and rotate the roll slowly to clean it.

Firstly, according to our observation the laser cleaning of the roll with Comexi like oscillating beam system as a mobile cleaning takes from 60 to 120 minutes for a working length 1360mm.

Secondly, as a result of a cleaning with a such beam sweep system overheat areas on the surface can appear. It can happen as a result of unequal overlapping if the beam sweeps on the surface of the anilox roll.

Highest cleaning quality and the absolute safety of the anilox rolls is obtained by the relatively quick rotation during the cleaning with a speed of 5 rotations per second and by the focusing of the laser beam in a very small spot. One laser impulse of 1 MJ comes in one spot with a diameter of 100 microns only once. The control of energy distribution on the surface of the anilox roll enables to us to guaranty your safety and the lack of melted cells.

With a LaserEcoClean technology your anilox roll with a 1360 width is cleaned in 15 minutes.

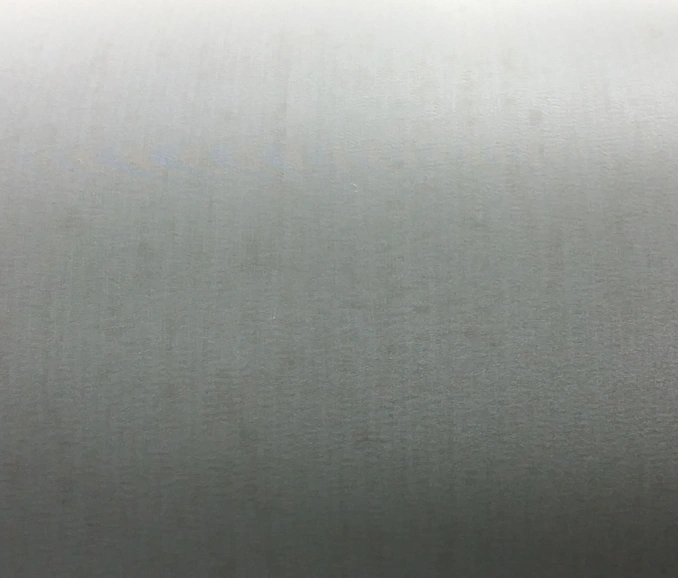

Bellow you can see the picture of the anilox surface cleaned with other laser cleaning technology (on the left) and with LaserEcoClean on the right.

01.

Other technology. You can see the structure of dark (clogged) cells and pale (overheated) areas.

02.

LaserEcoClean. You can see the roll before the cleaning on the left and after the cleaning on the right. The surface is cleaned homogeneously.

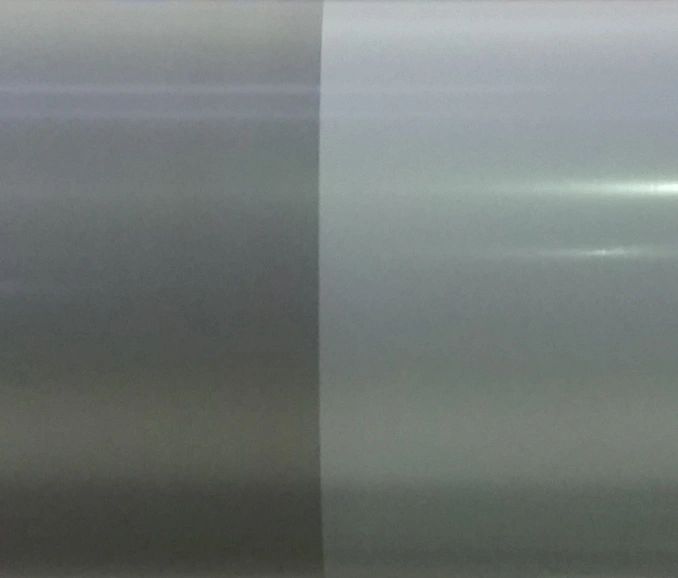

03.

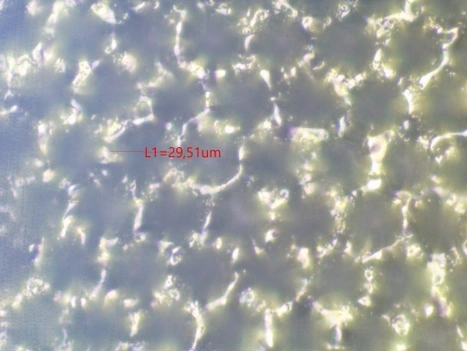

Other technology. Dark and pale areas with magnification x200. The area of the surface without cells is chosen.

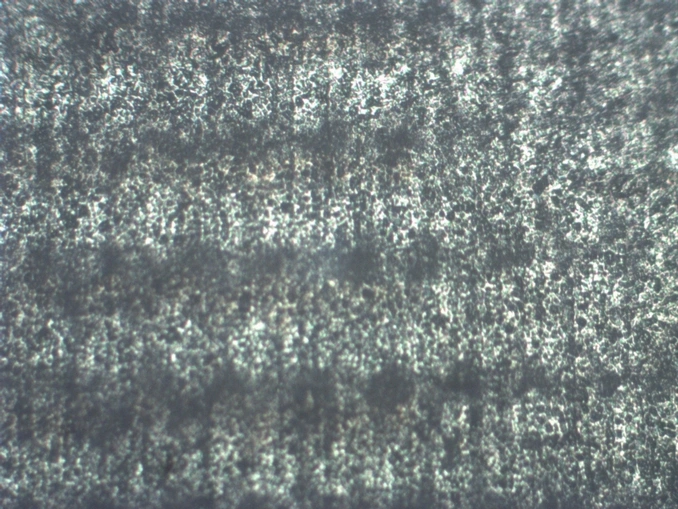

04.

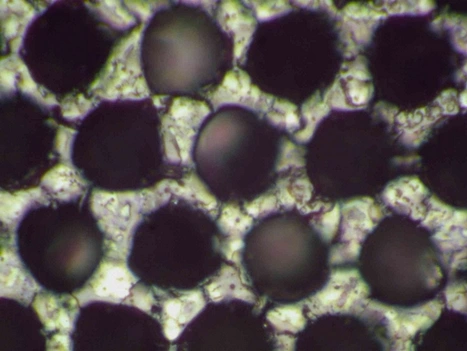

LaserEcoclean. The area of the surface without cells is chosen. The area on the left is clogged, the area on the right is cleaned. No spoors of the laser sweep can be seen.

There is a company, which produces equipment for laser cleaning of anilox rolls with short beam sweep. Their equipment needs approximately 8 hours to clean one anilox roll with a 1360 working length. It means that you are able to clean 1000 anilox rolls a year vs 17000 a year with LaserEcoClean.

To clean with a scanner laser takes less time, nevertheless, you have to increase power. This inevitably leads to the melting of the rolls surface.

Our team inspected anilox rolls on four printing facilities where such type of equipment was installed. The whole anilox park looked melted. We do not recommend using a scanner to clean the rolls.

Moreover, LaserEcoClean is an everyday safe deep cleaning solution. You are guaranteed are able to clean your anilox rolls with our equipment every day without any mechanical damage of the anilox roll surface. Some of our clients clean their anilox rolls with our stationary equipment more than 500 times.