Mobile cleaning > Why we?

ONLY WITH LASERECOCLEAN THE SAFETY FOR THE CHERAMICS OF YOUR ANILOX ROLLS IS GUARANTEED

Our cleaning team provides cleaning for anilox rolls since 2010 and guarantees in contract the safety of the LaserEcoClean technology.

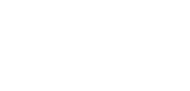

1. Research made by Zecher GmbH

First cleaning of anilox rolls for Zecher GmbH with LaserEcoClean technology was made in summer 2015. Anilox rolls with line screen more than 400 l/cm were cleaned. Zecher GmbH made extensive research of the ceramics structure before and after the cleaning and compared our results with our competitors. After the research Zecher decided to purchase the cleaning equipment from us. Please see the reference from Mr. Wand (technical director of the Zecher company) bellow.

"Since we are the market leader for varnish and ink anilox rolls we are also interested in the maintenance and cleaning of anilox rolls. Our emloyess are experts in production of high tech goods. They know of course how to apply one or another type of anilox rolls in production and consequentially the anilox cleaning issue arises. So, we have to provide our customers with a solution to such issues. Until recently we were using chemical and ultrasonic cleaning methods. As a producer of anilox rolls, we are frequently requested for a nontrivial cleaning solution. In the recent past, we could not clean all aniloxes to the fullest satisfaction. That is why we decided to consider new technologies. During in last two years, we tried different types of laser cleaning equipment for anilox rolls. We chose the equipment from the company LaserEcoClean because we were convinced with the cleaning results and the safety. The deep cleaning equipment for anilox rolls LaserEcoClean was installed in our production facility in 2016 and first cleaning sessions completely fulfilled our high requirements."

Mr. Wand

(technical director of the Zecher company)

2. The safety guarantee

To measure the effect of the laser beam to the ceramics, we cleaned anilox roll with a LaserEcoClean technology more than 40 times.

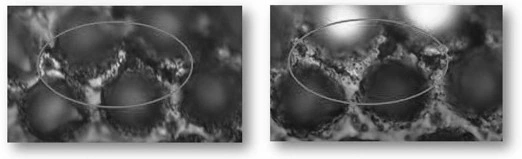

Please, see the microscopic photos of the anilox roll surface before the cleaning and after 40 cleaning sessions.

On the photos, you can see that the laser beam did not cause any damage to the anilox roll surface. Big cracks and caverns with size from 1 till 10 µm did not change their form or configuration. It happens due to the rightly tuned mode of laser cleaning.

Before cleaning After 40 cleanings

3. We are not afraid to make a microscopic photo the anilox roll before and after the cleaning.